OMISA WhiteLine Manual Hydraulic

The Manual Hydraulic Series of butt-welding machines in the WhiteLine generation makes a statement by its superior manufacturing quality and its scalability in the form of an easy upgrade to a data logging-enabled machine with the installation of an SPG 2.0 data logger for welding report logging.

The machine ships with a hydraulic unit that features, as a unique characteristic, a totally integrated enclosure that also is a splash and dirt shield for all components on the inside. The front panel controls, too, are included in the ingress protection according to the IP 54 rating (where IP 64 is possible upon request).

All connections, including an additional power socket free to use for the operator’s convenience, are located at the back of the controller. Both the facing tool and the heating element are also connected at the back panel of the hydraulic controller. Therefore, no additional power distribution unit is needed.

Welding monitoring system

Heating element temperature

Display screen

7-segment numerical characters, character height 10 mm

Hydraulic unit

- Only one supply needed, all connections and an additional power socket on the back of the enclosure

- Digital heating element temperature control, settable from the hydraulic unit

- Hydraulic unit in encased, rugged steel enclosure with a weight of as little as 19.5 kg (up to O.D. 355 mm)

- Max. pressure up to O.D. 355 mm, 130 bar; O.D. 500 - 630 mm, 150 bar; O.D. 800 - 1600 mm, 220 bar

- Welding pressures displayed on precise, maintenance-free manometer gauge

Hydraulic unit easily upgraded with SPG welding report logger:

- Pressure sensor 160 bar set into hydraulic system

- Dedicated support set onto the corner of the hydraulic unit for the data logger, made for harsh worksite environments

- Pressure and temperature connectors directly plugged into the hydraulic system via short lines

- Power supply to the data logger possible from the PE-wired power socket on the back of the hydraulic unit

Technical Specs

| Dimension | 160 mm | 250 mm | 315 mm | 355 mm | 500 mm | 630 mm | 800 mm | 1000 mm | 1200 mm |

| P/N | SP160EVO3 | SP250EVO3 | SP315EVO3 | SP355EVO3 | SP500EVO3 | SP630EVO3 | SP800EV5 | SP1000EV2 | SP1200EV3 |

| Operating range, O.D. | 40 - 160 mm | (63) 75 - 250 mm | 90 - 315 mm | 90 - 355 mm | (200) 250 - 500 mm | 315 - 630 mm | 500 - 800 mm | (630) 710 - 1000 mm | (630) 710 - 1200 mm |

| Power supply | 230 V | 230 V | 230 V | 230 V | 230 V | 400 V | 400 V | 400 V | 400 V |

| Frequency | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. | 50 Hz, 3 ph. |

| Rated power | 2.8 kW | 3.5 kW | 4.3 kW | 4.8 kW | 5.5 kW | 10.7 kW | 15.7 kW | 22.7 kW | 21.8 kW |

| Overall weight incl. of all components | 75.5 kg | 110 kg | 122 kg | 160 kg | 308 kg | 398 kg | 972 kg | 1418 kg | 1796 kg |

| Reducer inserts | 40 - 140 | (63) 75 - 225 | 90 - 280 | 90 - 315 | (200, 225) 250 - 450 | (250, 280) 315 - 560 | (400, 450) 500 - 710 | (630) 710 - 900 | (630) 710 - 1000 |

Components

Welding neck support

Welding neck support

| 160P.OR O.D. 160, 40 - 160 mm | 200P.OR O.D. 200, 63 - 200 mm | 250P.OR O.D. 250, 63 - 250 mm | 315P.OR O.D. 315, 90 - 315 mm |

| 355P.OR O.D. 355, 90 - 355 mm | 500P.OR O.D. 500, 200 - 500 mm | 630P.OR O.D. 630, 315 - 630 mm | 800P.OR O.D. 800, 500 - 800 mm |

| 1000P.OR O.D. 1000, 710 - 1000 mm | 1200P.OR O.D. 1200, 710 - 1200 mm | 1400P.OR O.D. 1400, 800 - 1400 mm | 1600P.OR O.D. 1600, 1000 - 1600 mm |

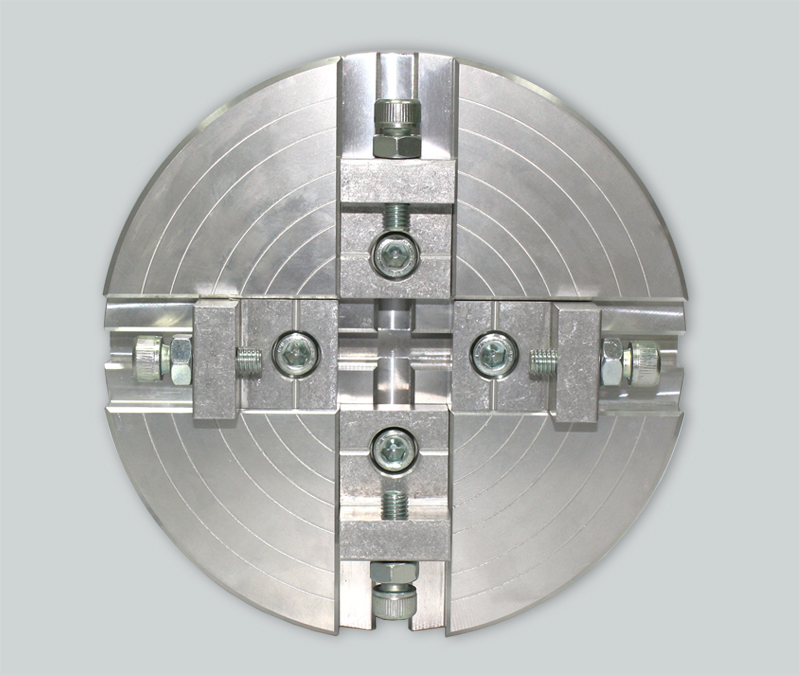

Set of aluminum reducers

Set of aluminum reducers

| RID.160PS 160 (D 40 - 140) | RID.250V1 250 (D 75 - 225) | RID.315PS 315 (D 90 - 280) | RID.355PS 355 (D 90 - 315) |

| RID.500PP 500 (D 250 - 450) | RID.630PP 630 (D 315 - 560) | RID.800PP 800 (D 500 - 710) | RID.1000PP 1000 (D 710 – 900) |

| RID.1200PP 1200 (D 710 – 1000) | RID.1400PP 1400 (D 800 – 1200) | On request 1600 (D 1000 – 1600) |

Set of steel reducers

Set of steel reducers

| R.STL160 160 (D 40 - 140) | R.STL250 250 (D 75 - 225) | R.STL315 315 (D 90 - 280) | R.STL355 355 (D 90 - 315) |